What You’ll Need to Start Your Own Screen Printing Business

Rob The T-shirt Guy January 25, 2019 0Although a screen printing business can appear stacked wall-to-wall with machinery, you actually only need a few pieces of equipment to get your printing business off the ground.

It can seem too much to handle. Running a screen printing business not only requires a highly technical skill set and an unwavering commitment to unbridled creativity, but it also requires a substantial investment in numerous pieces of expensive screen printing equipment. Although a screen printing business can appear stacked wall-to-wall with machinery, you actually only need a few pieces of equipment to get your printing business off the ground.

Shirt Design Equipment

The screen printing industry requires several pieces of equipment that help you come up with your shirt design masterpieces. Referred to as the pre-screen printing press process, you have to purchase equipment that turns ordinary wholesale t-shirts into attention-grabbing apparel that puts a brand’s best promotional foot forward.

Start by purchasing a computer that includes advanced graphics design software. Then, you need one or more screen printers to place black ink that completely blocks out harmful UV rays. You will need to buy screens, preferably a small number of common screens to get your screen printing business off the ground.

Here are some more shirt design equipment to consider for your screen printing business:

Screen Printing Equipment to Sell Promotional Products

For the carefully set prints you have created to bring brands alive, you need to invest in a few pieces of screen printing equipment. How many pieces of equipment you order for your new screen printing business depends on how much money you can afford. Many businesses in the screen printing industry purchase the most vital pieces of equipment for a grand opening. Then, they use cash flow to order complementary pieces of screen printing equipment to ramp up production

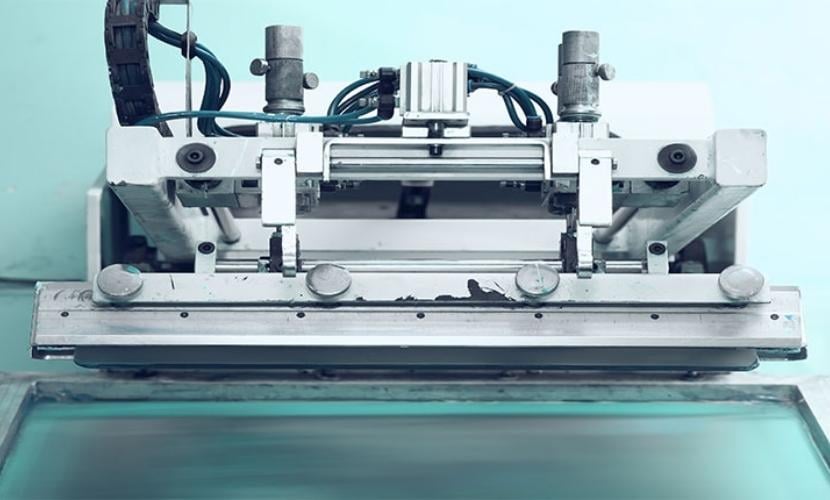

The first order for a screen printing business should be a reliable press. As the heartbeat of any screen printing business, a press can be a manual machine at the start to save the business money. However, as your cash flow grows from selling promotional products, you should consider upgrading to an automatic press that saves you money on labor and material costs.

Here are some other types of equipment and materials you will need for your screen printing business:

There is also the need to order post-press equipment for your screen printing business. You will need a conveyor dryer to heat ink to the proper curing temperature, which ensures your shirt designs last a long time. Your screen printing business also requires a heat sensor to detect temperatures that fall outside the acceptable range for screen printing equipment.

Why Buying Wholesale Shirts at Low Prices is Important

Buying wholesale clothing in bulk allows you to reap the financial benefit of saving money on the price of each shirt. The more shirts you buy in bulk from a wholesale clothing distributor, the lower the price you pay per unit. This is an especially helpful financial tip for school administrators and business managers that are responsible for ordering employee uniforms, as well as shirts to give away as brand promotions at civic events and industry trade shows.

Here are some more reasons why ordering wholesale shirts is important:

- Always a fresh look that exudes professionalism

- Opportunity to have potential customers see the shirts repeatedly

- Provides the perfect canvas for creative designs

- The perfect gift to hand out to job candidates at recruiting events

- Promote products and services in a subtle, yet effective manner

Buying bulk t-shirts for screen printing at wholesale prices allows you the leeway to experiment with your new equipment without breaking the bank. It also gives you a better profit margin when you start selling your new designs. Check out Bulk Apparel’s wholesale clothing for great quality at ridiculously low prices.