Streamlining Your T-Shirt Printing Process

Streamlining your t-shirt printing process means advanced technology, efficient workflows, and robust quality control for enhanced productivity and cost savings

Streamlining your t-shirt printing process is a pivotal step towards optimizing operational efficiency and fostering a more cost-effective and productive workflow. To achieve this, first consider investing in cutting-edge printing technology that can handle large volumes without compromising quality. Upgrading your machinery not only ensures faster production but also reduces downtime and maintenance costs in the long run.

Additionally, implementing a well-organized workflow is crucial. Designate specific stations for each stage of the printing process, from design creation and color separation to actual printing and quality control. This minimizes the risk of bottlenecks and confusion, enabling seamless collaboration among team members.

Adopting a just-in-time inventory management system can help mitigate excess material storage and associated costs. By ordering materials as needed, you can maintain a lean inventory, reduce waste, and optimize cash flow. Furthermore, explore automation options for repetitive tasks, such as color mixing and screen preparation, to further enhance efficiency and free up skilled labor for more specialized tasks.

Regularly assess and refine your processes based on performance metrics and customer feedback. Embrace a continuous improvement mindset to identify areas for enhancement and implement changes accordingly. This commitment to ongoing optimization will not only keep your t-shirt printing process efficient but also position your business to adapt to evolving market demands and technological advancements. In conclusion, by investing in technology, organizing workflows, optimizing inventory management, automating repetitive tasks, and maintaining a focus on continuous improvement, you can be successful in streamlining your t-shirt printing process for heightened efficiency, reduced costs, and overall enhanced productivity.

Digital Design And Approval:

Harnessing the power of digital design tools revolutionizes the creation and modification of t-shirt designs, offering a dynamic and efficient approach to the traditionally manual design processes. By leveraging advanced software and design applications, designers can explore a myriad of creative possibilities, experiment with diverse elements, and fine-tune every detail with precision. This not only enhances the overall design quality but also significantly accelerates the design iteration cycle.

In conjunction with digital design tools, the implementation of an online approval system marks a pivotal shift in the design approval process. This integrated system not only simplifies but also accelerates the often cumbersome and time-consuming approval workflow. Designers, clients, and stakeholders can seamlessly collaborate in a virtual environment, where they can view, provide feedback, and approve designs in real-time. This not only fosters better communication and understanding but also minimizes delays associated with the traditional back-and-forth approval process.

Automation In Pre-Press:

Investing in pre-press automation software is a strategic move for custom apparel printing businesses seeking to enhance efficiency and precision in the preparation of printing plates or screens. By integrating advanced automation tools into the pre-press workflow, companies can streamline and expedite tasks that traditionally demanded significant manual effort and time. One key advantage lies in the utilization of automated color separation tools, which revolutionize the color separation process. These tools not only accelerate the pace of color separation but also contribute to improved accuracy and consistency in reproducing colors. The software’s ability to analyze and separate colors with a high level of precision ensures that the final print output reflects the intended design with unparalleled fidelity.

Inventory Management:

Inventory management is a critical aspect of ensuring the smooth and efficient operation of a t-shirt printing business. To achieve this, it is essential to maintain a meticulously organized inventory comprising not only high-quality blank t-shirts but also inks and various printing materials. A well-structured inventory system facilitates easy access to products, reduces the risk of errors, and enhances overall productivity. In addition to organizing the inventory physically, implementing a modern tracking system such as barcodes or Radio-Frequency Identification (RFID) technology can significantly improve efficiency. These technologies allow for real-time monitoring and precise tracking of inventory levels, enabling timely replenishment of stock and preventing potential shortages.

Digital Printing Technology:

When it comes to digital printing, direct-to-garment (DTG) printing stands out as a remarkably efficient solution, especially for smaller production runs. One of its key advantages lies in the elimination of screens and setup time, streamlining your t-shirt printing process. This feature not only contributes to cost savings but also allows for quick turnarounds, making DTG an ideal choice for businesses catering to niche markets or producing limited-edition designs. The technology enables vibrant and intricate designs to be directly printed onto garments with precision and detail, offering a high level of customization.

Beyond direct to garment DTG, a broader exploration of various digital printing technologies can unlock even greater potential for businesses seeking faster and more efficient production methods. Technologies such as dye-sublimation printing and UV printing offer unique advantages in terms of versatility and the ability to print on a wide range of materials. Dye-sublimation, for instance, allows for vibrant full-color prints on 100% polyester shirts, while UV printing excels in printing on rigid surfaces like glass, metal, and wood. Embracing these advanced digital printing methods not only accelerates the production process but also opens up new avenues for creative expression and product diversification.

Batch Printing:

Batch printing is a strategic approach employed to enhance operational efficiency in streamlining your t-shirt printing process. This method involves grouping similar orders or designs together, capitalizing on the similarities to optimize resource utilization and minimize downtime. By consolidating similar tasks, batch printing significantly reduces setup times, allowing for a more continuous and streamlined workflow.

One of the key advantages of batch printing is its ability to boost output. With batch processing in place, apparel printers can handle multiple tasks in a systematic and organized manner. This not only expedites the completion of individual jobs but also ensures a more effective utilization of available resources. The increased throughput translates into higher productivity, enabling businesses to meet tight deadlines and handle larger workloads with greater ease.

Furthermore, batch printing is a cost-effective strategy, as it enables the maximization of resources. By grouping similar orders, there is a reduction in the need for frequent equipment adjustments and setup changes. This, in turn, minimizes the likelihood of errors and increases the overall reliability of the printing process. Businesses can benefit from economies of scale, as the efficiency gained through batch printing contributes to a more cost-efficient production environment.

Standardized Processes:

Standardized processes are essential for achieving consistency and efficiency in any operation, particularly in the realm of shirt printing. By standardizing your printing processes, you aim to minimize variations and errors that may arise during different stages of production. This involves the development and meticulous documentation of standard operating procedures (SOPs) for each key stage in the apparel printing process. These SOPs serve as comprehensive guides, outlining the precise steps and protocols to be followed, from the initial design phase to the final printout. Such a systematic approach ensures that all team members are on the same page and adhere to a unified set of guidelines, reducing the likelihood of discrepancies and enhancing overall quality control. Standardization not only streamlines workflows but also facilitates easier troubleshooting and continuous improvement. As technology evolves and personnel change, having standardized processes in place becomes increasingly crucial for maintaining a high level of printing precision and reliability.

Quality Control Measures:

Implementing robust quality control measures is crucial to uphold product standards and customer satisfaction. It is imperative to integrate comprehensive checks at various stages of the production process to identify and rectify errors in a timely manner. By doing so, potential issues can be addressed early on, preventing the escalation of problems and minimizing the likelihood of defective products reaching the market.

Another aspect of quality control is the regular calibration and maintenance of printing equipment. This ensures the consistent and reliable performance of the machinery, thereby contributing to the overall print quality. Regular calibration not only enhances the precision of the equipment but also extends its lifespan, reducing the risk of unexpected breakdowns that could disrupt production schedules. Additionally, maintaining a stringent schedule for equipment checks and upkeep reflects a commitment to operational excellence, fostering a culture of continuous improvement within the production environment.

In addition to the aforementioned quality control measures, a critical aspect specific to t-shirt production involves implementing a thorough inspection process for fabric and print quality. This can be achieved through having a partner wholesale t-shirt supplier that provides quality t-shirts for the business. At BulkApparel, our extensive selection includes a range of top-notch blank t-shirts that cater to diverse preferences and styles. Explore our curated collection of bulk t-shirts, designed to meet the demands of various occasions and preferences. Here are some sample items that showcase our commitment to quality:

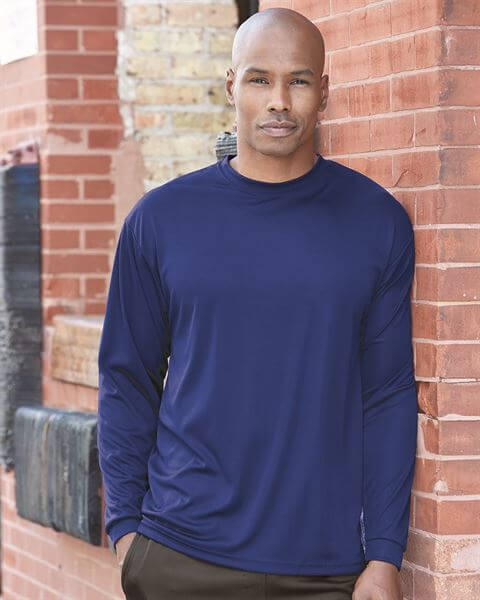

C2 Sport 5104 Performance Long Sleeve T-Shirt:

Elevate your performance with the C2 Sport 5104. This wholesale long sleeve t-shirt is crafted for those who demand both style and functionality. Made from premium materials, it ensures comfort and durability, making it an ideal choice for those looking to make a statement while staying active.

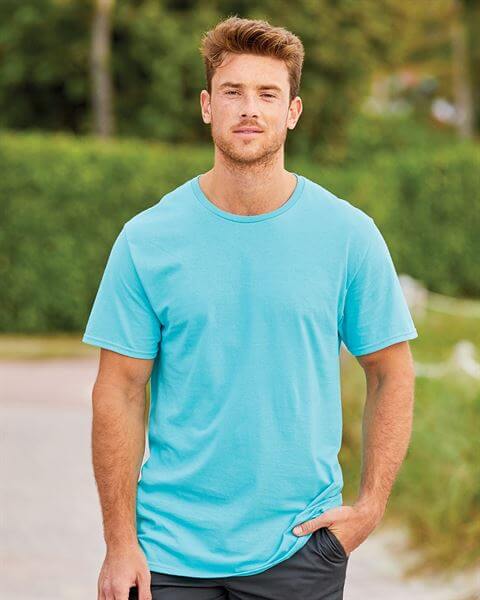

Paragon 200 Islander Performance T-Shirt:

Embrace the island vibes with the Paragon 200 Islander. This performance t-shirt combines style and comfort effortlessly. Whether you’re relaxing on the beach or engaging in outdoor activities, the Islander Performance Tee ensures you stay cool and look great in any setting.

Next Level 6610 Women’s CVC Crew:

The Next Level 6610 is designed for the modern woman who values both fashion and comfort. This women’s CVC crew tee offers a perfect blend of softness and durability, making it a wardrobe essential. Its versatile style allows you to dress it up or down for any occasion.

Fruit of the Loom SF45R Sofspun Crewneck T-Shirt:

Experience the unmatched softness of the Fruit of the Loom SF45R. This wholesale crewneck t-shirt combines a comfortable fit with a classic look, making it a staple for everyday wear. The Sofspun technology ensures a smooth feel against your skin, providing the ultimate comfort throughout the day.

Russell Athletic 64STTM Essential 60/40 Performance Tee:

The Russell Athletic 64STTM Essential Performance Tee is a testament to our commitment to quality. With a 60/40 blend, this tee offers superior comfort and moisture-wicking properties, making it an excellent choice for those who demand high-performance apparel without compromising on style.

BulkApparel consistently ensures that the quality of their products aligns with the standards of your business. We recognize the critical role that quality plays in establishing and maintaining a positive brand image. By consistently delivering products that not only meet industry benchmarks but also reflect a commitment to excellence, the company aims to forge lasting partnerships with businesses seeking reliable and superior merchandise. The dedication to quality extends beyond mere compliance with industry standards; it is a testament to BulkApparel‘s mission to be a trusted ally in meeting your quality standards and business’s unique needs.

Employee Training:

Provide ongoing training for your staff to keep them updated on the latest printing technologies and techniques. This continuous investment in learning ensures that your workforce remains well-equipped to adapt to the dynamic landscape of the printing industry. By staying abreast of advancements, employees can enhance their skills, leading to improved efficiency and productivity. Additionally, cross-train employees to handle multiple tasks, reducing dependence on a single skilled operator. This not only strengthens the versatility of your team but also safeguards against disruptions caused by unexpected absences or workload fluctuations. A diversified skill set among your staff fosters a more resilient and adaptable work environment, ultimately contributing to the overall success and sustainability of your printing business.

Consider implementing a structured training program that covers not only technical skills but also emphasizes collaboration, problem-solving, and customer service, creating a well-rounded workforce capable of meeting the diverse needs of your clients. Regularly assess the effectiveness of your training initiatives and adjust them to align with emerging industry trends, ensuring that your team remains at the forefront of innovation.

Collaborative Workflow:

Establishing a comprehensive and dynamic training program is essential for fostering a skilled and adaptable workforce. Continuous training initiatives are crucial to ensure that your staff remains well-versed in the latest advancements in printing technologies and techniques. This not only enhances their individual skill sets but also contributes to the overall efficiency and competitiveness of your business. Beyond just staying current with industry trends, consider implementing cross-training programs that enable employees to diversify their skill sets.

By cross-training, you reduce the risk associated with depending on a single highly skilled operator, thereby enhancing operational flexibility and resilience. This approach not only mitigates potential disruptions due to unforeseen circumstances but also empowers your team to collaborate seamlessly and interchangeably, creating a more agile and versatile workforce. Through a commitment to ongoing learning and cross-functional training, your employees can adapt to evolving challenges, making your business more resilient and better positioned for long-term success in the dynamic printing industry.

Invest in Up-to-Date Equipment:

Investing in the latest equipment is crucial for ensuring the efficiency and competitiveness of your printing business. Regularly upgrading and maintaining your printing equipment allows you to stay at the forefront of technological advancements, providing you with the opportunity to leverage the latest features and improvements in the industry. One key consideration is to opt for equipment with faster printing speeds, which not only enhances productivity but also allows you to meet tight deadlines and handle larger volumes of work. Additionally, prioritizing higher efficiency in your printing equipment can lead to cost savings in the long run, as it reduces energy consumption and minimizes downtime.

To make informed decisions, it’s essential to thoroughly evaluate the available options and optimize your choices based on your specific business needs. Conduct a comprehensive assessment of the features offered by different equipment models, considering factors such as print quality, color accuracy, and the ability to handle various paper types and sizes. Take into account the scalability of the equipment to ensure it can accommodate your growing business demands. Moreover, consider the compatibility of the equipment with emerging technologies, such as cloud-based printing solutions and mobile connectivity, to future-proof your operations.

The continuous success of a t-shirt printing business relies on its ability to adapt, evolve, and prioritize efficiency. By adopting a proactive approach to process evaluation and soliciting valuable input from employees, you can gain valuable insights into potential bottlenecks and areas for enhancement. Regularly reviewing performance data and customer feedback becomes a crucial tool in the pursuit of optimization.

The optimization of workflows, guided by the information gathered through evaluations, enables you to make informed decisions about resource allocation, technology upgrades, and training initiatives. This, in turn, contributes to a more seamless and productive t-shirt printing process. The implementation of efficient processes not only enhances internal operations but also has a direct impact on customer satisfaction. This is how you go about streamlining your t-shirt printing process.

Also having a reliable wholesale shirt supplier like BulkApparel is a key factor that can significantly contribute to the success of a t-shirt printing business. Streamlining your t-shirt printing process requires a reputable wholesale apparel supplier that ensures a steady and timely supply of wholesale blank t-shirts. This is essential for meeting customer demands and maintaining a consistent production schedule. Avoiding delays or shortages in your supply chain helps build trust with customers and prevents potential disruptions in your business operations.